As you all know, I am a huge fan in exploring the process of how luxury goods are made. It's never just about the final shoe, bag, etc that is purchased from the boutique for me. I need to know more. I have this innate love for craftsmanship which is why when Gucci shared with me the images of the making of these luxurious python boots from their FW 13 collection I was super excited. I remember I was totally lusting after them as soon as I saw them strut down the Milan runway a few months ago.

I can't wait for you to scroll down and discover the step by step process in how these gorgeous boots were made. It is truly delightful and a stunning display of exquisite craftsmanship by Gucci artisans. From the sketch, to the final packaging, please enjoy a sneak peak into what goes behind the making of these boots.

1. Design begins with the paper model and careful study of materials, colours and proportions.

2. The artisans make a careful selection of the precious python, taking care to consider the correct placement of the characteristic markings of the skin according to the desired design effect. In this case, the material is a python that comes from South-East Asia. The main features of this material are its glossy shine and soft feel. During the tanning phase, special products (oils and fats) are used to make the skins extremely soft.

3. The next operation consists in perfecting the outline required of the previously shaped leather by carefully cutting the border of the leather according to the pattern. This requires much attention and experience of the artisan who must consider again how the specific markings of the python need to appear on the finished product.

4. After the python skin has been cut out according to the paper model, the edges are carefully reduced to maintain the same thickness once the individual pieces are attached together and sewn.

5. Once the pieces of python have been prepared, the artisan proceeds to apply an adhesive in order to attach successively the inside lining.

6. The upper is carefully reinforced with a special lining in order to prevent breakage and ensure the resistance of the delicate python skin.

7. Then, the various parts of the upper are prepared to be sewn together. In this step the artisan must carefully match up the design of the python.

9. The artisan prepares the edges of the partially prepared upper for attachment of the zipper.

10. The assembly of the zipper is carefully followed in the smallest details. It is applied to the upper together with a border (to protect against abrasion on the client’s leg or clothing) with particular attention to the finishing and smooth functioning of the zipper pull.

11. Once the upper has been prepared and sewn, the form is inserted and the upper is further pulled and shaped according the shape of the last around the bottom of the foot bed.

12. The leather is then also shaped around the heel and attached to the midsole.

13. Once the python has been shaped and fixed to the midsole the artisan uses a special abrasive tool to reduce and even out the thickness of the leather that has been gathered. This will ensure that no wrinkles create discomfort under the foot.

14. The artisan places and positions the small metal Gucci plaque onto the sole.

15. Based on the particular shape of the heel, it is constructed of reinforced steel with an ABS cup-shaped crown. The “leg” of the heel is necessarily formed of reinforced steel to guarantee the required strength of the shape considering the extremely reduced dimensions at the bottom of the heel – 5mm.

16. To realize the covering of the heel, an adhesive is applied and then the artisan carefully applies the leather by hand onto the structure of the heel paying careful attention to obtain a smooth covering of the heel.

17. The finished heel.

18. The heel is then attached and fixed to the outer sole.

19. To complete the special colouring, the artisan proceeds with an extra step of hand-shading to further enhance the play of shading according the natural characteristics of the python.

20. The finished boot is then finished with the application of a hot ironing tool.

|

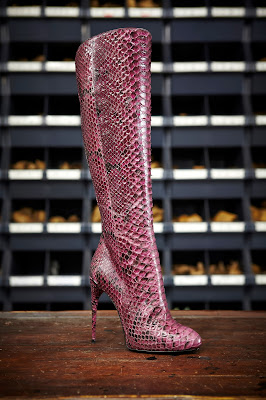

| The Finished Boot |

Image Courtesy: Gucci

No comments:

Post a Comment